industrial robot

In 1954, George Devol, an American, applied for the patent of "programmable articulated material transfer device", and cooperated with Joseph engelberg to establish the world’s first robot company Unimate, and developed the world’s first industrial robot Unimate. In the following decades, industrial robots not only changed the automobile manufacturing industry, but also expanded to other manufacturing and non-manufacturing industries, and experienced the cradle stage to the practical stage. With the progress and deepening of computer technology, robots are gradually developing towards multi-sensor intelligent control.

"1. Definition and classification of industrial robots"

1) The definition of industrial robot

Robots used in industrial fields are called industrial robots. Industrial robot is a mechatronics equipment that integrates advanced technologies of machinery, electronics, control, computer, sensors, artificial intelligence and other disciplines, and is known as one of the three supporting technologies of industrial automation. The definition of industrial robot varies from country to country in the world, and with the continuous development of robot technology and the gradual enrichment of its connotation, the definition of industrial robot is also changing.

American Industrial Robot Association (RIA), Japanese Industrial Robot Association (JIRA), German Standard (VDI) and International Organization for Standardization (ISO) have all defined industrial robots. At present, the definition of industrial robot adopted by the International Organization for Standardization (ISO) is widely used, that is, "an industrial robot is a manipulator with automatic control, repeatable programming, multi-functions and multiple degrees of freedom, which can carry materials, workpieces or operating tools to complete various operations". China’s current recommended national standard "Vocabulary of Robots and Robotic Equipment" (GB/T 12643— 2013), which is equivalent to adopting the ISO 8373:2012 standard of the International Organization for Standardization and following the definition of industrial robots by the International Organization for Standardization.

2) Composition of industrial robots

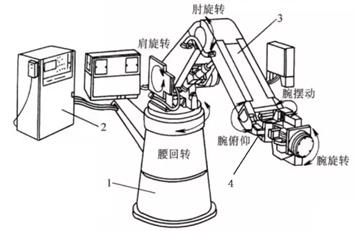

Industrial robot is composed of four parts: actuator (1 and 3 in Figure 1), control system (2 in Figure 1), drive system (such as hydraulic cylinder, motor, etc.) and detection system.

Fig. 1 Composition of industrial robots

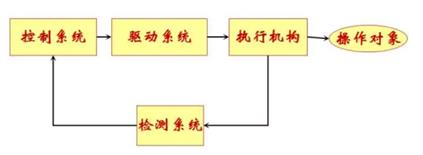

The operational relationship between these four parts is shown in Figure 2. The control system transmits signals to the drive system, drives the actuator to act, detects the execution results of the actuator monitored by the system, and feeds them back to the control system to adjust the control signals in time.

Fig. 2 Relationship between parts of industrial robot

(1) the executing agency.Executive mechanism is a mechanical device that has similar action function to human arm and can grasp and place objects or perform other operations in space, usually including base, arm, wrist and end effector. See 1 and 3 in Figure 1.

(2) Control system.The control system is the brain of the robot, which controls the robot to move according to the prescribed program, and memorizes the instruction information such as action sequence, motion trajectory, motion speed, etc., so as to realize repeated motion.

(3) Drive system.The drive system is a transmission device that amplifies the control command signal sent by the control system and drives the actuator to move. Common methods are electric, hydraulic, pneumatic and mechanical.

(4) detection system.The detection system mainly detects the movement position and state of the execution system, and feeds back the actual position and state information to the control system in real time. The control system compares it with the set value, and adjusts the instructions sent to the drive system in real time, so that the execution system can reach the set position and state. The detection system is usually various sensors.

3) Classification of industrial robots

Industrial robots can be classified in many ways: ① according to the program input mode, they can be divided into two types: programming input type and teaching input type; ② According to the driving mode, it can be divided into hydraulic driving, pneumatic driving and electric driving. ③ According to the mechanical structure, it can be divided into serial robots, parallel robots and serial-parallel hybrid robots; ④ According to the form of motion coordinates, it can be divided into five types: cylindrical robot, spherical robot, rectangular robot, multi-joint robot and SCARA robot. ⑤ According to the application fields, it can be divided into welding robots, assembly robots, handling robots, palletizing robots, loading and unloading robots, packaging robots, spraying robots and cutting robots. ⑥ According to the load, it can be divided into small load robots (load less than 20kg), medium load robots (load between 20 and 100kg) and large load robots (load greater than 100kg).

"2. Development trend of industrial robots"

Industrial robots are programmable, anthropomorphic, universal and mechatronics. Programmable means that industrial robots can be reprogrammed with the change of their working environment. Therefore, it plays an important role in the small batch and multi-variety flexible manufacturing process, can play a balanced and efficient function and value, and is one of the important components of flexible manufacturing system. Personification refers to the mechanical structure of industrial robots with actions similar to human walking and waist turning, as well as big arms, small arms, wrists, claws and other parts. Universality means that except specially designed industrial robots, general industrial robots have good versatility when performing different tasks; For example, changing the end effector (gripper, tool, etc.) of industrial robots can perform different tasks. Mechatronics means that industrial robots realize the organic combination of mechanical technology, microelectronics technology and information technology, and are typical mechatronics products.

The advantages of industrial robots in manufacturing industry are mainly reflected in automation, high efficiency and safety. With the increasingly prominent value of industrial robots in the development of modern manufacturing industry, industrial robots are showing the following development trends:

1) Industrial robots are becoming intelligent.

The development of industrial robots can be divided into three stages, that is, from the first generation of teaching and reproducing robots (teaching and storing information, reading these information at work, and sending instructions to actuators, which are widely used in welding, loading and unloading, painting and handling, etc.), to robots with simple sensory systems (with vision, touch and other functions, which can complete operations such as detection, assembly and environmental detection), and then to intelligent robots (not only

At present, most robots used in industry are not intelligent. Therefore, intelligence is the main development direction of industrial robots in the future. In terms of manipulator technology, it will develop in the direction of improving power density, universality, light weight, multiple degrees of freedom, multiple materials, imitating human body structure, high load-to-weight ratio and integrated mechanism. In terms of sensing and perception, through the use of sensors such as identification, tracking, force perception and vision, we can realize the independent identification of various external environments and various complex operations. In terms of security technology, industrial robots have evolved from their own security in the stand-alone era to network security in the Internet of Things era. In navigation technology, industrial mobile robots are developing towards multi-modal, outdoor and unmarked natural navigation.

2) Industrial robots move from single machine to multi-machine cooperation.

At present, the application of industrial robots is still dominated by single-machine automation, but the cooperative application of multiple robots has been realized in some application scenarios. For example, in automobile body painting, welding and other scenes, it is often necessary to have multiple robots working together in one station. At the same time, mainstream manufacturers of industrial robots have also launched multi-robot collaborative application solutions for these scenes. Take Yaskawa Electric as an example. At the China International Industry Fair in 2020, Yaskawa Electric demonstrated the multi-robot collaborative application of the white body welding and spraying station of commercial vehicles. Among them, in the painting station of white body of commercial vehicle, Yaskawa Electric demonstrated that four different robots, such as painting robot and door-opening robot, were used to complete the painting work of the body together; In the welding station of white body of commercial vehicles, many types of robots are also configured in one station to complete the handling, spot welding and arc welding operations. In order to achieve efficient production, multi-machine cooperative operation of industrial robots will have more applications.

3) Traditional industrial robots will move towards man-machine integration.

Traditional industrial robots have weak perception and can only work in a stable environment, that is, they mainly perform various deterministic tasks in a structured environment, otherwise they are prone to make mistakes and even hurt people and destroy things. In order to overcome the above shortcomings, effectively expand and extend human capabilities, inclusive robots came into being and represented the development direction of industrial robots in the future. The so-called inclusive robot refers to a robot that can naturally interact with the working environment, people and other robots, adapt to the complex dynamic environment independently and work cooperatively. "Harmony" includes three meanings: natural interaction between robots and environment, mutual assistance and complementarity between robots, and cooperative work between robots and people. In order to achieve the above goals of coexistence, cooperation and integration with the environment, other robots and human beings, robots need to innovate in "body", "perception" and "consciousness".

4) Compound industrial robots become a trend.

In order to meet more diverse application scenarios, there are many compound industrial robots, such as truss manipulator, orbital robot, mobile cooperative robot (AMR/AGV+ cooperative robot) and so on, which are used for mobile operation of industrial robots. Fig. 3 is a KUKA linear sliding rail robot and a KUKA mobile robot KMR iiwa. Linear slide rail is equivalent to adding another shaft to industrial robots, thus increasing the working space of industrial robots. On the same linear slide rail, multiple robots can usually be used. KUKA mobile robot KMR iiwa makes human-computer cooperation more flexible.

Figure 3 KUKA linear sliding rail robot and KUKA mobile robot KMR iiwa (Source: KUKA official website)

5) The application industries and scenes of industrial robots are constantly expanding.

The world’s first industrial robot was applied to the automobile industry. Up to now, the automobile industry is still the largest application market for industrial robots, and it is also the market with the highest standards and the highest use density. But at the same time, industrial robots are also expanding into general industries, and the application scenarios are deepening. In industrial applications, industrial robots have rapidly expanded to 3C electronics, metal processing, medical care, tobacco, logistics, food, pharmaceuticals, plastics, rubber, chemical industry and other industries. In specific application scenarios, the applications of industrial robots include welding, spraying, polishing, gluing, loading and unloading, deburring, handling, assembly, sorting, packaging and testing.

6) The rise of cloud robots and industrial robot cloud platforms.

In the intelligent manufacturing production scene, industrial robots are required to have the ability of self-organization and collaboration to meet flexible production, which brings the demand for cloud robots (robot brains are in the cloud) and industrial robot cloud platforms. Compared with traditional robots, clouded robots need to be connected to the control center in the cloud through the network, based on a platform with ultra-high computing power, and control the manufacturing process in real time through big data and artificial intelligence. In the future, with the development of technologies such as 5G, AI and cloud computing, cloud robots and industrial robot cloud platforms will become a new round of development hotspots.